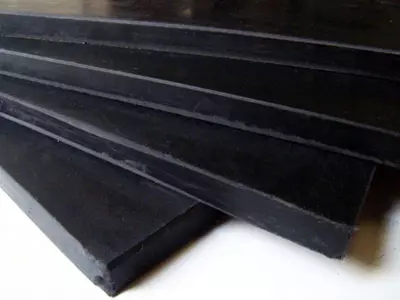

EPDM Rubber

Elastomer with maximum deterioration-resistance due to weather exposure and high temperatures, resists continuous outdoor exposure in extreme weather, extremely resistant to ozone.

EPDM is one of the most versatile rubbers, standing out for its excellent performance in outdoor applications. It is highly resistant to aging even when exposed to the most aggressive external conditions: water vapor, ultraviolet rays, ozone, saltpeter or extreme weather conditions.

EPDM

The main advantages of EPDM are its excellent resistance to oxidation, ozone and tear effects. They are very flexible, so high levels of fillers and plasticizers can be added while maintaining good physical properties and allowing the production of functionally economical blends.

Highest resistance to oxygenated solvents such as ketones, alcohols, aldehydes, ethers and esters

Physical and chemical properties: EPDM Rubber

- Shore “A” hardness: 60-65

- Tensile strength, minimal: 1050, 400 PSI

- Elongation, minimal: 550, 500 %

- Temperature Range: -13°F a 284°F

- Oils: Bad

- Acids: Good

- Outdoors: Excellent

- Abrasion: Medium

EPDM compound was specifically developed to manufacture gaskets or elastomers with very good resistance to weathering, dilute acids, and good resistance to concentrated acids.

Product Dimensions

- Plate: 3'3" x 3'3", 1/16" to 3" thickness

- Sheets: 3'3" x 32'9 " long, with 1/16" to 5/16" thickness

- Sheets: 3'3" wide x 16'4" long, with 3/8" to 5/8" thickness

The most common applications of HULE EPDM are found in the Automotive, Car, Maritime, Railway or Mining Industry.